Products and Solutions

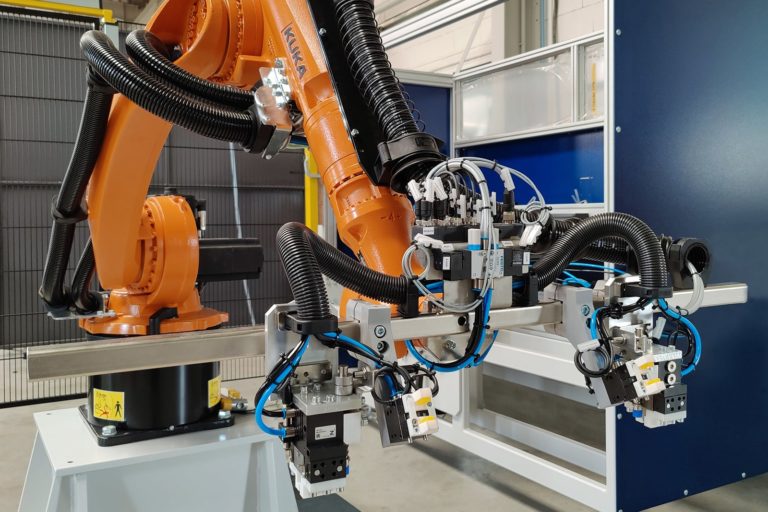

As a special machine builder, we accompany you along your process chain from the feeding of individual components to the packaging of your finished product.

In doing so, we serve all industries. A close cooperation based on partnership is our priority.

Thus, we support you from the first idea to the optimal manufacturing process. We develop concepts on the basis of your specifications, produce a corresponding layout already for the submission of the non-binding offer and subsequently ensure by means of a detailed design that our product corresponds exactly to your idea.

A digital twin is the virtual image of a machine, which is however alive in comparison to a CAD construction. Even before the physical machine exists, the digital twin enables the simulation of processes, the testing of programs.

As an official partner of Keyence, we maintain a close cooperation with the specialists in camera technology. The result of this cooperation is our highly flexible, modular and compact Feedercell.

The Cobot Welding System from MPA Technology offers an easy entry into the world of automated welding.

One thing unites our customers although they belong to different industries: The increasing pressure on prices.

In order to maintain competitiveness, the automation of manufacturing processes has become essential.

STEP BY STEP TO THE FINAL PRODUCT

1. YOUR IDEA

Do you want to reduce the manufacturing costs of your existing products, increase your output, or introduce a new product and make the manufacturing process efficient from the start?

2. CONSULTING AND PLANNING

We are happy to work with you to determine the path that will lead to the achievement of your production goals.

3. CONCEPT DEVELOPMENT

According to your requirements and wishes we develop a first automation concept.

4. NON-BINDING OFFER

If you like our concept, we determine in detail what is necessary for an implementation and create your individual offer.

5. DETAIL DESIGN

Once the technical and commercial details have been clarified, we proceed to the detailed design of your application. During this phase we are happy to keep you informed by means of regular updates. Upon request, a digital twin of your system can be created, which considerably simplifies the subsequent commissioning as well as the maintenance of your machine.

6. MANUFACTURING PROCESS

Now we move from the digital to the physical world. Your project will be assembled, wired and programmed in our plant. Our project managers will send you regular updates during this process and remain available to you at all times. We would be happy to welcome you to Burbach for an on-site inspection or, at the latest, a preliminary acceptance.

MPA Technology GmbH

Carl-Benz-Str. 31a

57299 Burbach

Germany

Production

Carl-Benz-Str. 35

57299 Burbach

Germany

Phone: +49 (0) 2736 20099-0

Email: info@mpa-tec.com

MPA auf LinkedIn MPA auf LinkedIn

MPA auf Facebook MPA auf Facebook